Integrated Piping System (IPS)

Integrated Piping System

The Future of Multi-Heating and Cooling

It’s time to say goodbye to traditional seven-pipe systems. Williams’ next-generation two-pipe system is powered by a building’s domestic water supply, providing lower installation costs and higher operational savings—all while eliminating the need for dedicated comfort system piping.

Our two-pipe system is whisper-quiet, reliable, and LEED-friendly to provide the ultimate comfort. Take advantage of your building’s existing piping infrastructure to provide on-demand, 24/7 heating and cooling.

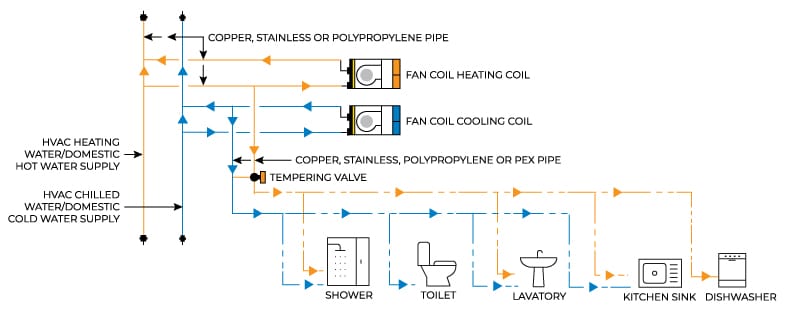

Typical Fan Coil / Plumbing Fixture Piping Diagram

The Recommendations are:

- Piping material for IPS ONDemand mains and runout piping to fan coils should be Copper, Stainless Steel or Polypropylene.

- Piping material for plumbing fixtures should be Copper, Stainless Steel, Polypropylene or PEX.

What powers it?

Our proprietary fan-coil technology utilizes the potable water supply already existing in the building.

Explore Savings With Williams

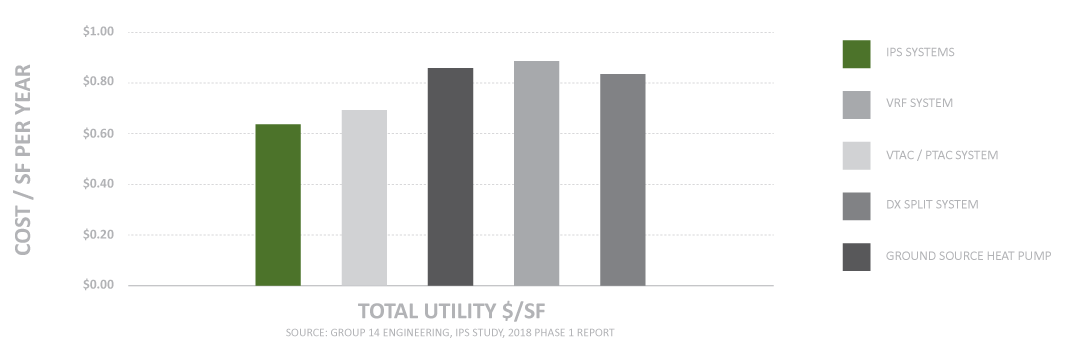

Williams’ two-pipe system offers a cost-effective, scalable solution for domestic heating and cooling applications. Compared to traditional seven-pipe systems, our cutting-edge offers wide-ranging savings, including:

- 15% less to operate and maintain

- 20% reduction in labor costs

- 30% less to build

- 5x less refrigerant needed

- 60% less piping

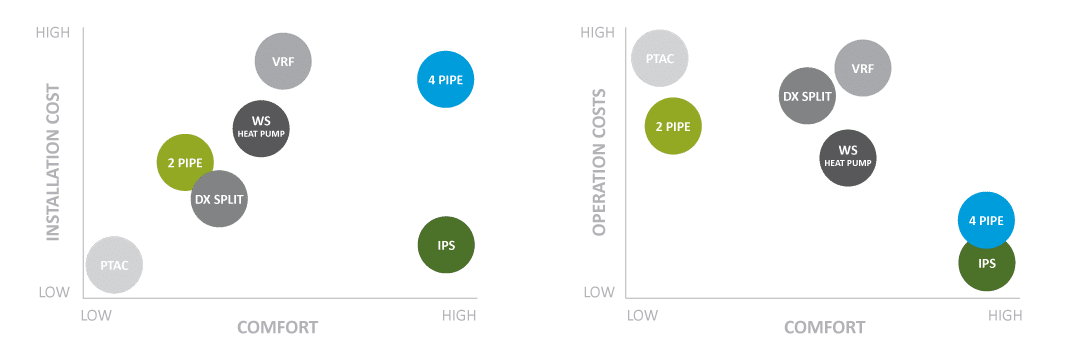

A Better Solution

Resources

Hydronic Resources

- Hydronic Industry Alliance – Commercial (HIA-C) Website

- “H20 Accepted”

- Building Efficiency System Tool (BEST) Resources

- Hydronic vs. VRF – which, when and why?

Case Studies

- Mariposa: Integrated Piping System Outperforms in Denver | Watch Video

- Williams Integrated Piping System (IPS) at The Atlantic in Philadelphia, PA

- Williams IPS Selected for Hewing Hotel Renovation

Additional Documents

Accessories

Maximize Savings and Efficiency

TRACvalve™

Valuable performance value at a fixed cost!

The TRACvalve™ variable fan coil is a budget-friendly, cost-efficient solution to increase comfort through air temperature control. With TRACvalve™, the system’s central pumps use less horsepower to provide heating and cooling. In addition, TRACvalve™ improves central plant efficiency by moderating and lowering the overall energy demand.

TRACvalve™ adjusts to the design LAT, maintaining a high Delta-T across the coil. Variable fluid flow reacts to room and system changes, reducing the GPM at a load mode demand. Overall, TRACvalve™ variable fan coils offer an efficient solution for any indoor environment in which tracking and adjusting to real-time variable load is critical.

| The TRACvalve Advantage | With TRACvalve, you get: |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

ComforTRAC™

A totally variable fan coil

The ComforTRAC™ from Williams has the ability to recognize changing room conditions and adjust automatically, matching real time variable load in virtually any indoor environment for the ultimate in comfort conditioning. Since moving BTUs in water is a superior method than moving them in air, the result is a higher level of comfort with lower system costs and greater energy efficiency. The ComforTRAC™ totally variable fan coil is the demand-controlled fan coil, offering variable CFM, GPM, LAT and dehumidification. Ideal applications include classrooms, conference and meeting rooms, dorms, suites, common areas or any space where discriminating occupant demand for comfort is required.

Design Features

- Performance is demand-controlled and matches heating and cooling load in any climate.

- Energy consumption is also demand-controlled as the load is continuously monitored and matched as needed. This allows the ComforTRAC™ unit to “sip” capacity from the main chiller system or boiler far more efficiently than conventional systems.

- Open protocol-compatible, may easily be incorporated into building automation systems (BAS). BTL certified BACNet.

- Coil design minimizes flow requirements and increases design Delta-T which reduces pipe size and the associated sizing of mains and central system components.

- Leaving air temperature control (LAT) delivers comfort and quick response at the unit. The unit is continuously recomissioning itself to space and system variations.

- Self-balancing and cleaning capabilities eliminate flow control devices, strainers and test ports saving capital and operating costs.

| Features | Advantages |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|